In a world, where NATO cannot protect you, as seen in recent months, and where terrible accidents can occur, Kärcher Futuretech (KFT) forms the last line of defence.

KFT, based in Schwaikheim, Germany is an internationally acknowledged specialist and a market leader in many aspects of protection and supply systems for mobile use in disaster and crisis zones. Using products and system solutions from KFT, civil defence, disaster relief, and military forces are able to supply large numbers of individuals with clean water and food, set up field camps, or carry out CBRN decontamination (decon). With its mobile, compact and modular solutions, KFT is a highly capable partner in the field of peace-keeping operations and disaster relief. Rounding off the company’s core areas of competence are highly competent advisory services for dealing with every kind of incident, worldwide servicing and a qualified training system.

KFT offers modern agents, devices and systems for the decon of personnel, equipment and infrastructure. Due to state-of-the-art decon methods and agents, e.g., the TEP 90 meets all technical requirements and the respective parameters required of a high-performance decon system. It has a consistent modular construction and includes all necessary components in the independently usable decon modules for mission-optimised thorough decon close to the affected troop. In addition to the TEP, the Bundeswehr has ordered seven (with an option of 10 more, up to 40) MEP Completely Modular Cage-based Decon Systems, in order to replace the E-Kfz Decon vehicles. Note: The Spanish have ordered the MEP as a stand-alone system for CBRN decon.

During the press-event of KFT's Decon Symposium, the company's Managing Directors Volker Welzenbach and Thomas Popp emphasised their other current developments as well, including the DSSM, the DSAP and the EDP, and the EDMP.

The MEP Cage Module System is a unique cage system, according to the company, feasible for most transport options. It has a low centre of gravity and a huge water volume. Also known as the Cage Based Modular Decon System, KFT is extending its existing range with it to include a modular decon system. The flexible configuration of individual modules known as cages allows this new system to be deployed in line with changing demands. The modules can be simply mixed and matched, offering space for whichever devices, chemicals or accessories as the scenario requires. Thanks to the use of an internally developed fixing system, the modules can be quickly and securely fixed together and onto a platform.

The system encompasses a variety of elements for the decontamination of items such as vehicles, road sections, interior spaces or individuals. A generator module is also provided for an independent power supply. Another unit is used as a water tank with a volume of around 1,500 litres. Standardised, simple controls ensure the utmost operating simplicity, while a central power connection also allows the operating output of the individual modules to be registered. The frames of the compact cage are made of aluminium, and their lightweight design even makes the system suitable for air transportation.

KFT has developed a new decon system for items of equipment in a French-German joint project. The DSSM (Decontamination System for Sensitive Material) is up and ready to operate within less than an hour following an atomic, biological or chemical incident. It comprises two modules, each capable of independent operation, which can be used to decontaminate both hardwearing items of equipment and also sensitive material such as electronic devices.

The system comprises two container modules: The CPE (Container Personal Equipment) and CSE (Container Sensitive Equipment), which are deployed depending on the equipment material and type of contamination involved. In the CPE unit, biological and chemical decontamination of thermally resistant objects is performed using the hot gas or hot steam method. Wet chemical treatment of moisture-resistant A, B and C-contaminated materials is also possible. Sensitive optical and electronic devices are treated in the CSE module in two vacuum chambers following a B or C incident.

The system is designed for particularly rapid deployment: Trained users are capable of erecting and commissioning the decontamination station in response to an emergency within just 15 minutes. The standardized size (each module is a 10ft ISO container) also ensures extreme ease of mobility, facilitating simple transportation of the containers by land, sea or air.

KFT’s new flexible solution for personal decontamination is the DSAP (Decontamination System for Ambulatory Persons), which is a container-based system capable of decontaminating up to 180 individuals an hour following atomic, biological or chemical incidents. The system even offers sufficient space for treating the injured. It permits flexible configuration, is quickly ready for deployment and is also simple to operate.

Depending on requirements, the system is available in a variety of different versions: The basic container houses three shower lines. The version with four shower lines is capable of decontaminating up to 180 persons every hour. To treat non-ambulatory subjects, two lines can be connected together. Air-supported tents are connected both in front of and behind the container for undressing and undressing and for registration of individuals being treated. The number of tents can be increased to as many as four, simplifying adjustment to country-specific circumstances and creating a private space. Self-decontamination of personnel takes place in additional add-on tents. The DSAP and was born out of a requirement with the Spanish Armed Forces.

Anther new system is the DSVP, a decon container still in R&D with the Netherlands.

Future outlook according to the managing directors include semi-automatic decon and further development of decon agents.

|

| Kärcher Futuretech’s TEP 90 during their Decon Symposium. (All Photos: Kärcher) |

KFT, based in Schwaikheim, Germany is an internationally acknowledged specialist and a market leader in many aspects of protection and supply systems for mobile use in disaster and crisis zones. Using products and system solutions from KFT, civil defence, disaster relief, and military forces are able to supply large numbers of individuals with clean water and food, set up field camps, or carry out CBRN decontamination (decon). With its mobile, compact and modular solutions, KFT is a highly capable partner in the field of peace-keeping operations and disaster relief. Rounding off the company’s core areas of competence are highly competent advisory services for dealing with every kind of incident, worldwide servicing and a qualified training system.

KFT offers modern agents, devices and systems for the decon of personnel, equipment and infrastructure. Due to state-of-the-art decon methods and agents, e.g., the TEP 90 meets all technical requirements and the respective parameters required of a high-performance decon system. It has a consistent modular construction and includes all necessary components in the independently usable decon modules for mission-optimised thorough decon close to the affected troop. In addition to the TEP, the Bundeswehr has ordered seven (with an option of 10 more, up to 40) MEP Completely Modular Cage-based Decon Systems, in order to replace the E-Kfz Decon vehicles. Note: The Spanish have ordered the MEP as a stand-alone system for CBRN decon.

During the press-event of KFT's Decon Symposium, the company's Managing Directors Volker Welzenbach and Thomas Popp emphasised their other current developments as well, including the DSSM, the DSAP and the EDP, and the EDMP.

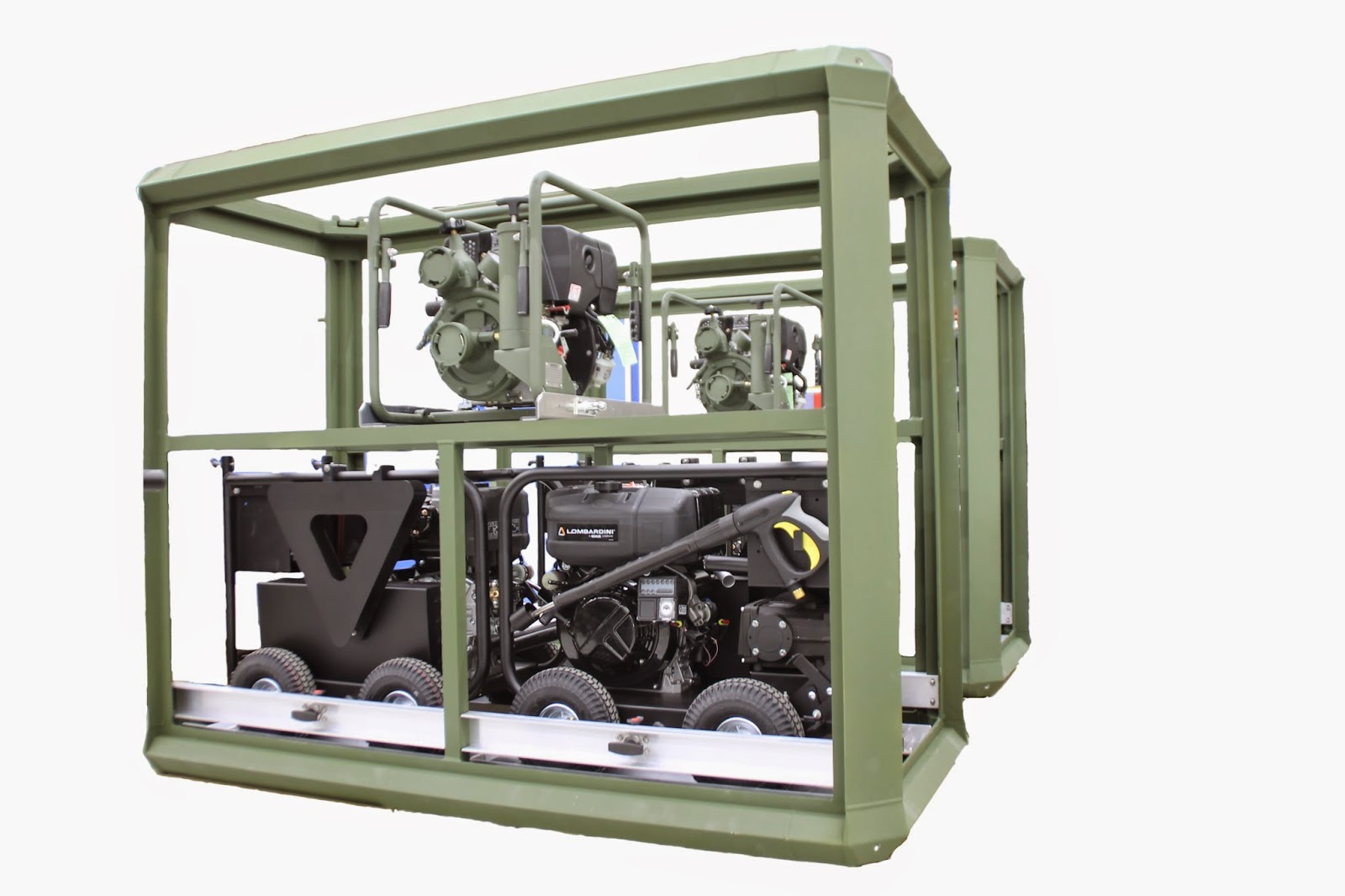

The MEP Cage Module System is a unique cage system, according to the company, feasible for most transport options. It has a low centre of gravity and a huge water volume. Also known as the Cage Based Modular Decon System, KFT is extending its existing range with it to include a modular decon system. The flexible configuration of individual modules known as cages allows this new system to be deployed in line with changing demands. The modules can be simply mixed and matched, offering space for whichever devices, chemicals or accessories as the scenario requires. Thanks to the use of an internally developed fixing system, the modules can be quickly and securely fixed together and onto a platform.

|

| Open Cage. |

The system encompasses a variety of elements for the decontamination of items such as vehicles, road sections, interior spaces or individuals. A generator module is also provided for an independent power supply. Another unit is used as a water tank with a volume of around 1,500 litres. Standardised, simple controls ensure the utmost operating simplicity, while a central power connection also allows the operating output of the individual modules to be registered. The frames of the compact cage are made of aluminium, and their lightweight design even makes the system suitable for air transportation.

|

| The MEP being unloaded from vehicle. |

KFT has developed a new decon system for items of equipment in a French-German joint project. The DSSM (Decontamination System for Sensitive Material) is up and ready to operate within less than an hour following an atomic, biological or chemical incident. It comprises two modules, each capable of independent operation, which can be used to decontaminate both hardwearing items of equipment and also sensitive material such as electronic devices.

The system comprises two container modules: The CPE (Container Personal Equipment) and CSE (Container Sensitive Equipment), which are deployed depending on the equipment material and type of contamination involved. In the CPE unit, biological and chemical decontamination of thermally resistant objects is performed using the hot gas or hot steam method. Wet chemical treatment of moisture-resistant A, B and C-contaminated materials is also possible. Sensitive optical and electronic devices are treated in the CSE module in two vacuum chambers following a B or C incident.

The system is designed for particularly rapid deployment: Trained users are capable of erecting and commissioning the decontamination station in response to an emergency within just 15 minutes. The standardized size (each module is a 10ft ISO container) also ensures extreme ease of mobility, facilitating simple transportation of the containers by land, sea or air.

KFT’s new flexible solution for personal decontamination is the DSAP (Decontamination System for Ambulatory Persons), which is a container-based system capable of decontaminating up to 180 individuals an hour following atomic, biological or chemical incidents. The system even offers sufficient space for treating the injured. It permits flexible configuration, is quickly ready for deployment and is also simple to operate.

|

| Kärcher FutureTech's DSAP. |

Depending on requirements, the system is available in a variety of different versions: The basic container houses three shower lines. The version with four shower lines is capable of decontaminating up to 180 persons every hour. To treat non-ambulatory subjects, two lines can be connected together. Air-supported tents are connected both in front of and behind the container for undressing and undressing and for registration of individuals being treated. The number of tents can be increased to as many as four, simplifying adjustment to country-specific circumstances and creating a private space. Self-decontamination of personnel takes place in additional add-on tents. The DSAP and was born out of a requirement with the Spanish Armed Forces.

Anther new system is the DSVP, a decon container still in R&D with the Netherlands.

Future outlook according to the managing directors include semi-automatic decon and further development of decon agents.